Heavy Duty Mining Nordberg C Series Primary Hard Stone Crushing Machine Jaw Crusher Price List

Descripción del producto

#detail_decorate_root .magic-0{border-bottom-width:2px;border-bottom-style:solid;border-bottom-color:#53647a;background-color:#c5ccde;margin-left:0;margin-right:0;padding-left:8px;padding-right:8px;color:#53647a;font-family:Roboto;font-size:24px;padding-top:8px;padding-bottom:4px}#detail_decorate_root .magic-1{vertical-align:top}#detail_decorate_root .magic-2{vertical-align:top;display:block;padding-right:4px;box-sizing:border-box;padding-left:4px}#detail_decorate_root .magic-3{vertical-align:top;padding-bottom:4px;box-sizing:border-box;padding-top:4px}#detail_decorate_root .magic-4{padding:0;margin:0;white-space:pre-wrap;font-size:14px}#detail_decorate_root .magic-5{margin:0;padding:0}#detail_decorate_root .magic-6{width:750px}#detail_decorate_root .magic-7{overflow:hidden;width:373px;height:257.166015625px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-8{margin-top:0;margin-left:0;width:373px;height:257.166015625px}#detail_decorate_root .magic-9{overflow:hidden;width:373px;height:257px;margin-top:0;margin-bottom:0;margin-left:4px;margin-right:0}#detail_decorate_root .magic-10{margin-top:0;margin-left:0;width:373px;height:261.36945304437563px}#detail_decorate_root .magic-11{padding:0;margin:0;color:#333;font-size:14px;white-space:pre-wrap}#detail_decorate_root .magic-12{padding:0;line-height:20px;margin:0}#detail_decorate_root .magic-13{color:#0000bf;font-size:x-large;font-family:inherit;font-style:inherit;font-variant-ligatures:inherit;font-variant-caps:inherit}#detail_decorate_root .magic-14{overflow:hidden;width:750px;height:421.875px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-15{margin-top:0;margin-left:0;width:750px;height:421.875px}#detail_decorate_root .magic-16{overflow:hidden;width:750px;height:561.7977528089888px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-17{margin-top:0;margin-left:0;width:750px;height:561.7977528089888px}#detail_decorate_root .magic-18{font-size:18px}#detail_decorate_root .magic-19{overflow:hidden;width:750px;height:561.1111111111111px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-20{margin-top:0;margin-left:0;width:750px;height:561.1111111111111px}#detail_decorate_root .magic-21{overflow:hidden;width:750px;height:823.327615780446px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-22{margin-top:0;margin-left:0;width:750px;height:823.327615780446px}#detail_decorate_root .magic-23{width:750px;border-collapse:collapse}#detail_decorate_root .magic-24{min-height:18px;padding:5px 10px;width:103px;min-height:18px;box-sizing:content-box}#detail_decorate_root .magic-25{min-height:18px;padding:5px 10px;width:81px;min-height:18px;box-sizing:content-box}#detail_decorate_root .magic-26{min-height:18px;padding:5px 10px;width:83px;min-height:18px;box-sizing:content-box}#detail_decorate_root .magic-27{min-height:18px;padding:5px 10px;width:87px;min-height:18px;box-sizing:content-box}#detail_decorate_root .magic-28{min-height:18px;padding:5px 10px;width:133px;min-height:18px;box-sizing:content-box}#detail_decorate_root .magic-29{min-height:18px;padding:5px 10px;width:515px;min-height:18px;box-sizing:content-box}#detail_decorate_root .magic-30{min-height:18px;padding:5px 10px;width:514px;min-height:18px;box-sizing:content-box}#detail_decorate_root .magic-31{min-height:18px;padding:5px 10px;width:132px;min-height:18px;box-sizing:content-box}#detail_decorate_root .magic-32{display:none}#detail_decorate_root .magic-33{min-height:18px;padding:5px 10px;width:516px;min-height:18px;box-sizing:content-box}#detail_decorate_root .magic-34{text-align:center;padding:0;line-height:20px;margin:0}#detail_decorate_root .magic-35{vertical-align:top;display:inline-block;padding-right:4px;width:33.33%;box-sizing:border-box;margin-bottom:-4px;padding-left:4px;margin-top:-4px}#detail_decorate_root .magic-36{vertical-align:top;box-sizing:border-box;padding-top:4px}#detail_decorate_root .magic-37{width:244.656px;height:234px;overflow:hidden}#detail_decorate_root .magic-38{position:relative;left:-25px;top:0;width:312px;height:234px}#detail_decorate_root .magic-39{padding:0;font-size:16px;line-height:20px;color:#333;margin:0}#detail_decorate_root .magic-40{position:relative;left:0;top:-16.25px;width:198px;height:268.2px}#detail_decorate_root .magic-41{padding:0;line-height:20px;font-weight:bold;margin:0}#detail_decorate_root .magic-42{text-align:center}#detail_decorate_root .magic-43{position:relative;left:0;top:0;width:244.77px;height:234px}#detail_decorate_root .magic-44{padding:0;font-size:16px;line-height:20px;font-weight:bold;color:#333;margin:0}#detail_decorate_root .magic-45{text-align:center;padding:0;line-height:20px;font-weight:bold;margin:0}#detail_decorate_root .magic-46{position:relative;left:0;top:0;width:177.1px;height:231px}#detail_decorate_root .magic-47{position:relative;left:-22.5px;top:0;width:312px;height:234px}#detail_decorate_root .magic-48{position:relative;left:0;top:0;width:244.656px;height:244.656px}#detail_decorate_root .magic-49{overflow:hidden;width:750px;height:885px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-50{margin-top:0;margin-left:0;width:750px;height:885px}#detail_decorate_root .magic-51{overflow:hidden;width:750px;height:320px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-52{margin-top:0;margin-left:0;width:792px;height:316.8px}#detail_decorate_root .magic-53{text-align:left;margin:0;padding:0}#detail_decorate_root .magic-54{overflow:hidden;width:750px;height:661px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-55{margin-top:0;margin-left:0;width:750px;height:661.5px}#detail_decorate_root .magic-56{text-align:center;margin:0;padding:0}#detail_decorate_root .magic-57{overflow:hidden;width:750px;height:863px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-58{margin-top:0;margin-left:0;width:750px;height:862.5px}#detail_decorate_root .magic-59{overflow:hidden;width:750px;height:2174px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-60{margin-top:0;margin-left:0;width:750px;height:2174px}#detail_decorate_root .magic-61{padding:0;font-size:16px;line-height:20px;margin:0}#detail_decorate_root .magic-62{overflow:hidden;width:184.5px;height:203.30578512396693px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-63{margin-top:-1.2706611570247932px;margin-left:0;width:369px;height:258px}#detail_decorate_root .magic-64{overflow:hidden;width:184.5px;height:203.30578512396693px;margin-top:0;margin-bottom:0;margin-left:4px;margin-right:0}#detail_decorate_root .magic-65{margin-top:0;margin-left:-166.45661157024793px;width:351px;height:246px}#detail_decorate_root .magic-66{margin-top:0;margin-left:0;width:163px;height:230px}#detail_decorate_root .magic-67{margin-top:0;margin-left:0;width:184px;height:261px}#detail_decorate_root .magic-68{padding:5px 10px;overflow:hidden;width:655px;box-sizing:content-box}#detail_decorate_root .magic-69{padding:5px 10px;overflow:hidden;width:164px;box-sizing:content-box}#detail_decorate_root .magic-70{padding:5px 10px;overflow:hidden;width:98px;box-sizing:content-box}#detail_decorate_root .magic-71{padding:5px 10px;overflow:hidden;width:543px;box-sizing:content-box}#detail_decorate_root .magic-72{font-size:large}#detail_decorate_root .magic-73{overflow:hidden;width:750px;height:554px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-74{margin-top:0;margin-left:0;width:750px;height:553.5px}#detail_decorate_root .magic-75{overflow:hidden;width:750px;height:349px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-76{margin-top:0;margin-left:0;width:750px;height:349.047px}#detail_decorate_root .magic-77{font-weight:bold;text-align:center}#detail_decorate_root .magic-78{color:#00f;font-size:x-large;font-weight:bold} Product Description SGS CE ISO Certificated Coal Crusher Price Iron Crusher Quality Guaranteed Pe400X600 Jaw Crusher

Double Roller Crusher Introduction:

Double roller crusher, a kind of mining machinery, is also called counter roller crusher. Mainly used to crush ore. This machine has the advantages of small size, large crushing ratio (5-8), low noise, simple structure, convenient maintenance, uniform particle size of crushed materials, low over-crushing rate, convenient maintenance, sensitive overload protection, safety and reliability. It is more suitable for the crushing of raw coal (including gangue) in large coal mines or coal preparation plants. The tooth roller crusher has a large crushing capacity, and the motor and the reducer are connected by a limit-type hydraulic coupling to prevent power overload and sensor overload protection, which is safe and reliable. The gear roller spacing is adjusted hydraulically, and the gear roller bearings are centrally lubricated. Optimal design of tooth shape, selective crushing of tensile and shear forces, high efficiency and low consumption, and even granulation. Double Roller Crusher Application Field:

It is suitable for coal, metallurgy, mining, chemical industry, building materials and other industries.

Double Roller Crusher Suitable Material:

Double roller crusher is suitable for medium and fine crushing of solid materials with compressive strength less than 250MPA and moisture less than 35%, such as crushing iron ore, quartz stone, potassium (sodium) feldspar, limestone, river pebble, metal Silicon, barite, basalt, granite, steel slag, cement clinker, construction waste (concrete), shale, quicklime, coal, coke, clay, bentonite, chemical raw materials, etc. It can be widely used in mining, thermoelectricity, cement ceramics, metallurgy, chemical industry, building materials and other industries. It has the characteristics of low maintenance cost, low moisture requirements, reliable performance, low power consumption, less dust and low noise.

Performance Characteristics Of Double Roller Crusher: The double roller crusher is equipped with two crushing rollers.It is composed of motor, bracket, fixed roller, movable roller and safety spring. The roller surface is mostly smooth, and the bearing of the movable roller can be moved along the frame, and it is pressed against the strong safety spring. When the particularly hard object falls in, the bearing can be removed and the object can be spit out. Before normal operation, the gap between the two rollers should be adjusted with shims to ensure the crushing ratio. Suitable for medium broken viscous stone According to the granularity required by the user, the roller surface is divided into flat roller surface and surfacing roller surface. The flat roller surface model is suitable for feeding with a particle size of less than 80mm. 1-10mm fine crushing operation, surfacing stick noodle machine is suitable for medium and fine crushing operation where the feed particle size is less than 150mm and the finished product particle size requires 5-30mm.

Advantages :

1. Equipped with PDG-II roller crusher in the grinding system, the production capacity of the grinding equipment can be fully exerted, generally the output can be increased by 30%-40%, and the total energy consumption can be reduced by 20%-30%. 2. Compact structure, light weight and small volume, for the grinding system with the same production capacity requirements, equipped with PDG-II roll crusher can significantly save investment. 3. Simple structure, small space occupation, convenient operation and maintenance. 4. The dustproof board is installed inside, which has good sealing performance, avoiding the splashing of small materials after crushing, less dust, low working noise, and greater improvement in working environment. 5. The optimized design of the abrasive roller body, the machine does not need to replace the roller body of the grinding machine for life, and the old type roller pair machine needs to be dismantled for overhaul and replaced the roller body within one year. 6. The replaceable wear-resistant lining board is installed on the grinding roller of the roller crusher. The wear-resistant lining board adopts domestic advanced wear-resistant materials, which has the advantages of long service life, not easy to damage, and convenient maintenance. The continuous service life can reach more than one year. When the wear is serious, the cover can be replaced by removing the cover. The amount of maintenance is small and the cost is low, which is unmatched by any other type of crusher in China. 7. The roller crusher is equipped with a safety protection device. When an accidental metal iron piece enters the crushing cavity, the protection device acts and the iron piece leaks out of the equipment to operate normally. 8. The roll gap of the grinding roller body of the roller crusher can be adjusted arbitrarily from 1mm to 20mm. After adjusting the roll gap according to the requirements of the crushing particle size, the crushing particle size can be reliably controlled, and all are discharged from below the crushing cavity with the ideal particle size. 9. Simple and reasonable structure, low operating cost, stable operation, high efficiency and energy saving, high crushing efficiency, adjustable output granularity. 10. The roller crusher is the working principle of low speed and high pressure roller extrusion. The material falls vertically into the crushing cavity from the upper part of the crusher, and is crushed by the strong pressure generated between the two rollers. Most of the material has become powder, and a large number of cracks have occurred in the remaining small portion of granular material. In the further crushing process, it can greatly reduce the grinding energy consumption and increase the output.

Double Roller Crusher Product Details

The double roller crusher uses high squeezing force generated by the relative rotation of two high-strength wear-resistant alloy crushing rollers to crush the material. After the material enters the gap between the two rollers (v-shaped crushing chamber), it is crushed by the relative rotation of the two crushing rollers Under the action of pressure and shear force, the material is crushed into the required particle size and discharged from the discharge port under squeezing, shearing and grinding.If the compressive strength of the material exceeds 250mpa, it is recommended to choose an energy-saving roller pressing (grinding) machine, which is divided into two methods: triangle belt and coupling transmission (hard link) according to user requirements. If there is no electric power in the mine plant , it can be changed to diesel or gasoline engine as power.

More Model Please Contact Us,the Model Also Can Be Customized

Related Products

Compound Cone Crusher

Single-cylinder Hydraulic Cone Crusher

Multi-cylinder Hydraulic Cone Crusher

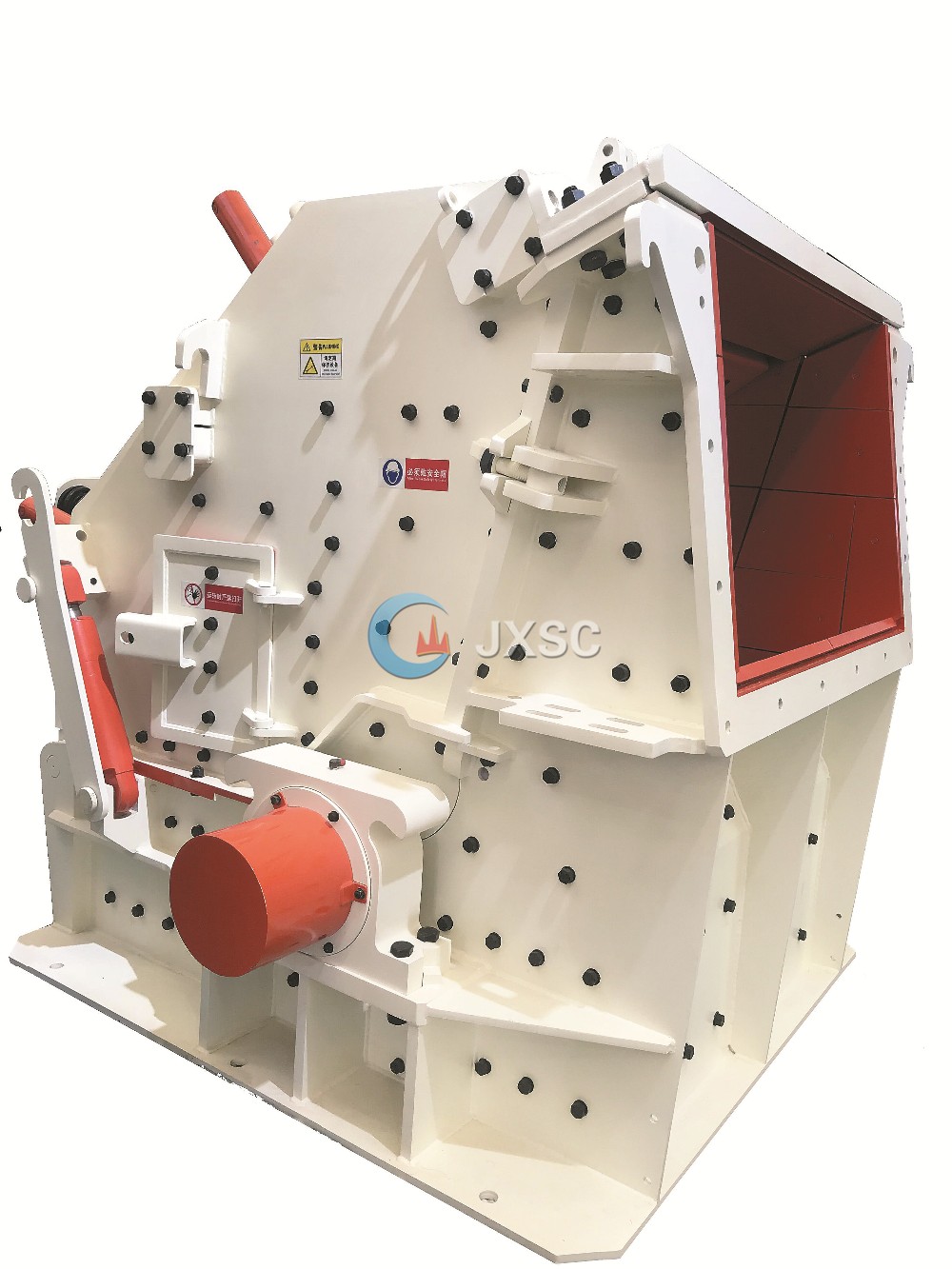

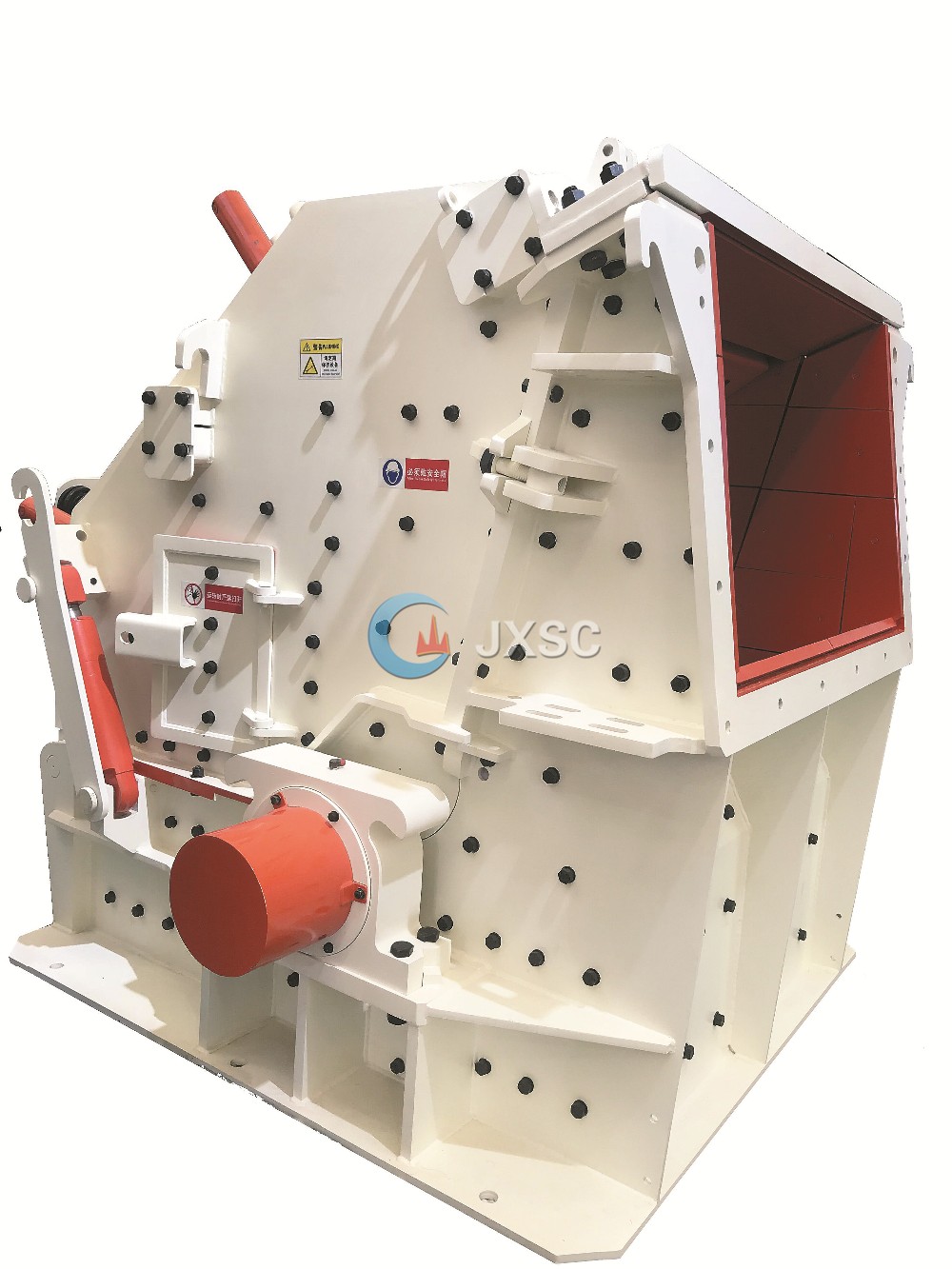

Impactcrusher

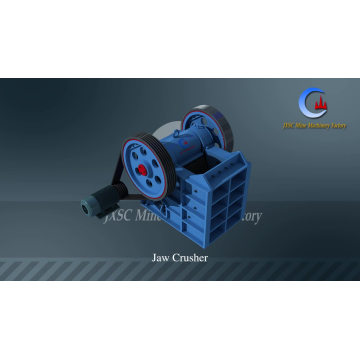

Jaw Crusher

Mobile Crushing Plant

About Company

About Company  Jiangxi shicheng Mine Machinery Factory was established in 1985, it's a professional machinery factory special in mining equipment research, manufacturing, sales and offers professional mine processing plant work flow design, plant installation, equipment maintenance, beneficiation processing technology guidance service as one of the metallurgical machinery equipment factory. Our products are exported to Africa,Nigeria,Zambia,Zimbabwe,Congo,Uganda,Mozambique,Angola,Southeast Asia,South America and many other countries and regions.We are committed to creating high quality and efficient crushing and screening equipment,quality is our eternal pursuit and responsibility.

Jiangxi shicheng Mine Machinery Factory was established in 1985, it's a professional machinery factory special in mining equipment research, manufacturing, sales and offers professional mine processing plant work flow design, plant installation, equipment maintenance, beneficiation processing technology guidance service as one of the metallurgical machinery equipment factory. Our products are exported to Africa,Nigeria,Zambia,Zimbabwe,Congo,Uganda,Mozambique,Angola,Southeast Asia,South America and many other countries and regions.We are committed to creating high quality and efficient crushing and screening equipment,quality is our eternal pursuit and responsibility.

Our Workshop

Our Workshop  Our Customers

Our Customers

Certification

Our Services ●Pre-sales service: We provide you with the prophase plan, process flow design and manufacturer equipment according to your special demand.

Our Services ●Pre-sales service: We provide you with the prophase plan, process flow design and manufacturer equipment according to your special demand.

●Sales service: Send technicians to the jobsite guiding the installation and adjustment, training operators and finishing the check and accept together with you.

●After-sales service: To establish long term friendship, we will reg-ularly pay return visit to customers. Supplying technique, building design, instruction, installation and debugging for free.

●Lifelong service: One year warranty to make sure your machine runs constantly.Always offer lifelong service and provide spare parts for a long term.

●How long is the guarantee?

All of our products are guaranteed for one year. If products quality is not consistent with the description as we described or the promise before you place order, we promise 100% refund.

●What is the delivery time?

According to the specific data provided by the customer,our customized crushing machine`s delivery time is 30-48 days.

●What is the nearest port?

Xiamen, Guangzhou, Shenzhen

●What is the trade terms?

CIF,FOB,DDU ect is acceptable.

●Service and Payment Terms?

We can accept T/T and L/C; 30% deposit, 70% balance before delivery, which is international trade practice; Finished product pictures will provide to customers before delivery.

Packing & Delivery

Shiping by Sea/Air Freight

or Any Way the Customer Requires

Double Roller Crusher Introduction:

Double roller crusher, a kind of mining machinery, is also called counter roller crusher. Mainly used to crush ore. This machine has the advantages of small size, large crushing ratio (5-8), low noise, simple structure, convenient maintenance, uniform particle size of crushed materials, low over-crushing rate, convenient maintenance, sensitive overload protection, safety and reliability. It is more suitable for the crushing of raw coal (including gangue) in large coal mines or coal preparation plants. The tooth roller crusher has a large crushing capacity, and the motor and the reducer are connected by a limit-type hydraulic coupling to prevent power overload and sensor overload protection, which is safe and reliable. The gear roller spacing is adjusted hydraulically, and the gear roller bearings are centrally lubricated. Optimal design of tooth shape, selective crushing of tensile and shear forces, high efficiency and low consumption, and even granulation. Double Roller Crusher Application Field:

It is suitable for coal, metallurgy, mining, chemical industry, building materials and other industries.

Double Roller Crusher Suitable Material:

Double roller crusher is suitable for medium and fine crushing of solid materials with compressive strength less than 250MPA and moisture less than 35%, such as crushing iron ore, quartz stone, potassium (sodium) feldspar, limestone, river pebble, metal Silicon, barite, basalt, granite, steel slag, cement clinker, construction waste (concrete), shale, quicklime, coal, coke, clay, bentonite, chemical raw materials, etc. It can be widely used in mining, thermoelectricity, cement ceramics, metallurgy, chemical industry, building materials and other industries. It has the characteristics of low maintenance cost, low moisture requirements, reliable performance, low power consumption, less dust and low noise.

Performance Characteristics Of Double Roller Crusher: The double roller crusher is equipped with two crushing rollers.It is composed of motor, bracket, fixed roller, movable roller and safety spring. The roller surface is mostly smooth, and the bearing of the movable roller can be moved along the frame, and it is pressed against the strong safety spring. When the particularly hard object falls in, the bearing can be removed and the object can be spit out. Before normal operation, the gap between the two rollers should be adjusted with shims to ensure the crushing ratio. Suitable for medium broken viscous stone According to the granularity required by the user, the roller surface is divided into flat roller surface and surfacing roller surface. The flat roller surface model is suitable for feeding with a particle size of less than 80mm. 1-10mm fine crushing operation, surfacing stick noodle machine is suitable for medium and fine crushing operation where the feed particle size is less than 150mm and the finished product particle size requires 5-30mm.

Advantages :

1. Equipped with PDG-II roller crusher in the grinding system, the production capacity of the grinding equipment can be fully exerted, generally the output can be increased by 30%-40%, and the total energy consumption can be reduced by 20%-30%. 2. Compact structure, light weight and small volume, for the grinding system with the same production capacity requirements, equipped with PDG-II roll crusher can significantly save investment. 3. Simple structure, small space occupation, convenient operation and maintenance. 4. The dustproof board is installed inside, which has good sealing performance, avoiding the splashing of small materials after crushing, less dust, low working noise, and greater improvement in working environment. 5. The optimized design of the abrasive roller body, the machine does not need to replace the roller body of the grinding machine for life, and the old type roller pair machine needs to be dismantled for overhaul and replaced the roller body within one year. 6. The replaceable wear-resistant lining board is installed on the grinding roller of the roller crusher. The wear-resistant lining board adopts domestic advanced wear-resistant materials, which has the advantages of long service life, not easy to damage, and convenient maintenance. The continuous service life can reach more than one year. When the wear is serious, the cover can be replaced by removing the cover. The amount of maintenance is small and the cost is low, which is unmatched by any other type of crusher in China. 7. The roller crusher is equipped with a safety protection device. When an accidental metal iron piece enters the crushing cavity, the protection device acts and the iron piece leaks out of the equipment to operate normally. 8. The roll gap of the grinding roller body of the roller crusher can be adjusted arbitrarily from 1mm to 20mm. After adjusting the roll gap according to the requirements of the crushing particle size, the crushing particle size can be reliably controlled, and all are discharged from below the crushing cavity with the ideal particle size. 9. Simple and reasonable structure, low operating cost, stable operation, high efficiency and energy saving, high crushing efficiency, adjustable output granularity. 10. The roller crusher is the working principle of low speed and high pressure roller extrusion. The material falls vertically into the crushing cavity from the upper part of the crusher, and is crushed by the strong pressure generated between the two rollers. Most of the material has become powder, and a large number of cracks have occurred in the remaining small portion of granular material. In the further crushing process, it can greatly reduce the grinding energy consumption and increase the output.

Double Roller Crusher Product Details

Model | Feeding Size (mm) | Discharging size (mm) | Capacity (t/h ) | Motor Power (kw) | Guard mode |

2PG400*200 | <25mm | 1-5 | 1.5-10 | 3*2 | Spring |

2PG400*400 | <35mm | 1-10 | 3-30 | 5.5*2 | |

2PG600*500 | <40mm | 1-20 | 6-50 | 15*2 | |

2PG800*600 | <60mm | 1-20 | 10-100 | 18.5*2 | |

2PG1000*800 | <80mm | 1-30 | 15-130 | 30*2 | The Hydraulic Spring |

2PG1200*800 | <90mm | 1-30 | 30-250 | 37*2 | |

2PG1200*1200 | <90mm | 1-30 | 40-350 | 55*2 | |

2PG1600*1200 | <110mm | 1-30 | 60-420 | 75*2 | |

2PG1600*1600 | <110mm | 1-30 | 75-550 | 110*2 | |

2PG1800*1600 | <120mm | 1-30 | 90-700 | 132*2 | |

2PG1800*1800 | <135mm | 1-30 | 100-900 | 200*2 |

More Model Please Contact Us,the Model Also Can Be Customized

Related Products

Compound Cone Crusher

Single-cylinder Hydraulic Cone Crusher

Multi-cylinder Hydraulic Cone Crusher

Impactcrusher

Jaw Crusher

Mobile Crushing Plant

About Company

About Company  Jiangxi shicheng Mine Machinery Factory was established in 1985, it's a professional machinery factory special in mining equipment research, manufacturing, sales and offers professional mine processing plant work flow design, plant installation, equipment maintenance, beneficiation processing technology guidance service as one of the metallurgical machinery equipment factory. Our products are exported to Africa,Nigeria,Zambia,Zimbabwe,Congo,Uganda,Mozambique,Angola,Southeast Asia,South America and many other countries and regions.We are committed to creating high quality and efficient crushing and screening equipment,quality is our eternal pursuit and responsibility.

Jiangxi shicheng Mine Machinery Factory was established in 1985, it's a professional machinery factory special in mining equipment research, manufacturing, sales and offers professional mine processing plant work flow design, plant installation, equipment maintenance, beneficiation processing technology guidance service as one of the metallurgical machinery equipment factory. Our products are exported to Africa,Nigeria,Zambia,Zimbabwe,Congo,Uganda,Mozambique,Angola,Southeast Asia,South America and many other countries and regions.We are committed to creating high quality and efficient crushing and screening equipment,quality is our eternal pursuit and responsibility.  Our Workshop

Our Workshop  Our Customers

Our Customers

Certification

Our Services ●Pre-sales service: We provide you with the prophase plan, process flow design and manufacturer equipment according to your special demand.

Our Services ●Pre-sales service: We provide you with the prophase plan, process flow design and manufacturer equipment according to your special demand.●Sales service: Send technicians to the jobsite guiding the installation and adjustment, training operators and finishing the check and accept together with you.

●After-sales service: To establish long term friendship, we will reg-ularly pay return visit to customers. Supplying technique, building design, instruction, installation and debugging for free.

●Lifelong service: One year warranty to make sure your machine runs constantly.Always offer lifelong service and provide spare parts for a long term.

●How long is the guarantee?

All of our products are guaranteed for one year. If products quality is not consistent with the description as we described or the promise before you place order, we promise 100% refund.

●What is the delivery time?

According to the specific data provided by the customer,our customized crushing machine`s delivery time is 30-48 days.

●What is the nearest port?

Xiamen, Guangzhou, Shenzhen

●What is the trade terms?

CIF,FOB,DDU ect is acceptable.

●Service and Payment Terms?

We can accept T/T and L/C; 30% deposit, 70% balance before delivery, which is international trade practice; Finished product pictures will provide to customers before delivery.

Packing & Delivery

Ways of Packing | ||

1 | Standard Parts Packed in the Wooden Cases | |

2 | Big Parts Packed by Plastic Membrane | |

3 | The Whole Machine is Loaded in the Container | |

Shiping by Sea/Air Freight

or Any Way the Customer Requires

Grupos de Producto : Planta trituradora de rocas > Rompe mandíbulas

Otros productos

Productos hot

piezas de trituradora de alto contenido de manganesopiezas de la trituradora de conoequipo de minería de HYMAK trituradora de piedra trituradora de cono hidráulica minitrituradora de cantera trituradora de arena máquina trituradora de cuarzo precioPlanta trituradora de 70 TPHpiezas symons linder del cuenco buena quanlity trituradora de cono repuestos piezas de desgastebuenas piezas de desgaste de las piezas de repuesto de la trituradora de cono de la quanlityPEF0609 proveedor global profesional trituradora de mandíbula de gran tamaño y piezasPEF0609 proveedor global profesional trituradora de mandíbula de gran tamaño y piezasMaquinaria de mineral de hierro de alta calidad recientementeVenta caliente manual de trituradora de cono symons de alta calidadTrituradora de cono symons de alta calidad con el mejor precioBuen precio de la trituradora de cono de resortePrecio de la trituradora de cono de resorte de alta calidadTrituradora de cono systerm hidráulico monocilíndrico de alto rendimiento Y250Trituradora de cono hidráulico monocilíndrico de alto rendimiento Y315